It can be shocking to think of how many items that you interact with on a daily basis, are a result of metal stamping. The lamp in your bedroom, the frame to your bathroom mirror, the silverware you use for breakfast; these are all results of metal stamping. How these various, and unique, items get their particular shape and style comes down to which type of metal stamping was used. Some of these various styles can use additional techniques like chemicals, pressure, or heat to form the metals into their designated shape. Most types of metal stamping begins with sheet metal that is then form with a unique mechanical force. Let’s take a look at some of the different styles of metal forming that are available:

Bending

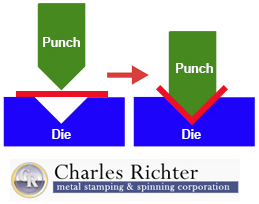

When a product, for example, has a need for a 90° angle, it can use bending to help achieve its shape. Robotic machines or press brakes use force to bend the metal. The image to the right shows an example of how this method works.

When a product, for example, has a need for a 90° angle, it can use bending to help achieve its shape. Robotic machines or press brakes use force to bend the metal. The image to the right shows an example of how this method works.

Coining

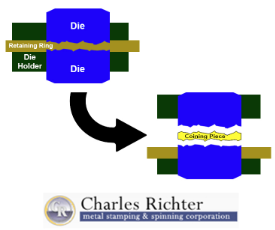

Coining, as it is aptly named, is the type of metal stamping that is used in the production of such items as coins, buttons, badges, or other items with precision parts. Coining consists of exposing material(s) to extremely high stress levels to produce a fine surface. This cold working process uses a mechanical press or a hydraulic press. The diagram to the left shows an example of the coining process.

Deep Drawing

Deep Drawing, or deep drawn stamping, is the art of turning a flat piece of sheet metal into a unique three-dimensional form. This process can be used for candle cups, cone-shaped products, scalloped edged products, or filigrees, to name a few. Deep drawing metal stamping is also extensively customizable and, due to the custom die, offers extensive cost-savings when buying in bulk. View the video below to see one of the ways that Charles Richter executes deep drawing.

Roll Forming

When it comes to creating a piece that requires a consistent profile throughout the entirety of the piece, you would want to look to roll forming as the means to create your part. This is achieved by rolling curled sheet metal through a series of consistent, rotating, dies to produce a uniform final part. An example of a product that could use roll form metal processing would be the rain gutters you find on the sides of your house.

Stamping

Much like the other types of metal forming we’ve looked at thus far, metal stamping uses dies to form sheet metal into various sizes, shapes, or objects. Weather you are looking for a piece no larger than a nickel, or a large piece for an industrial machine- all formed metal experiences some type of stamping. View the videos below for some examples of Charles Richter’s metal stamping.

Depending on your product and your needs, it is these processes, or a combination of them, that can produce the custom item specifically as you need! Interested in seeing this process in action? You can follow along with one of our skilled technicians and they work through the steps to create a custom piece in the video below.

Regardless of what type of metal product you are looking for, there is a metal stamping or forming option available to you. If you are not sure which procedure will best fit your needs, why not talk to the experts who have been working with custom metal stamping for over 100 years? At Charles Richter Metal Stamping, their expert staff can walk you through the process and answer any of the questions you may have regarding metal stamping. Find out today why Charles Richter is one of the leading metal stamping shops in the Northeast.