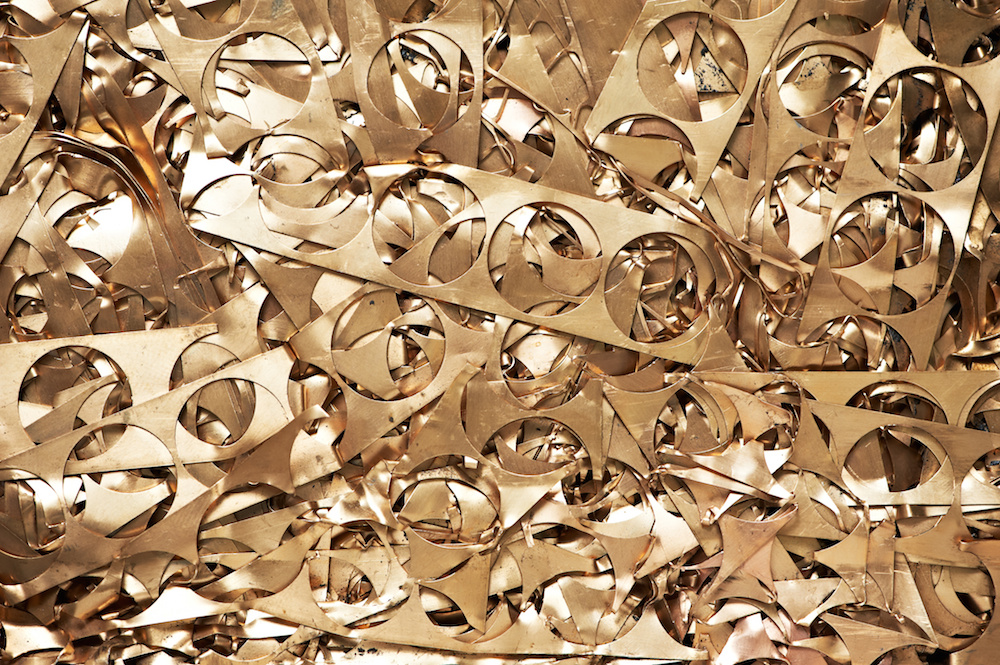

Brass Stampings

One of the most commonly requested metals here at Charles Richter is brass. Brass deep drawn stamping is used for a wide range of industries due to its unique characteristics and benefits. Those industries in which we transform brass into shapes and decorative pieces include the lighting, automotive, and telecommunications industries.

Deep drawn brass is easily shaped and offers excellent drawing properties.When brass deep drawn stamping takes place, it is common that the brass being used has lead added, although it is a very small amount. The addition of lead enhances the machinability of the brass. Brass is flexible and has a low melting point of 900 to 940 °C, 1652 to 1724 °F, making it easy to form and popular metal to use in deep drawn stamping. It’s also worth to note how elegant and beautiful brass stamped products look because of their shiny, golden finish, making it popular for items that are showcased for viewing. Its unique color makes it a nice choice for those metal products that have a more decorative purpose. Taking brass through the deep drawn process leaves it with greater physical strength than the unworked base brass material.

Properties of Brass:

- An alloy of copper and zinc

- Ideal in flammable or explosive environments

- Relatively low-friction

- Relatively low melting point

- Most of it can be and is recycled

- Not ferromagnetic

Benefits of Brass:

- Nonferrous metal

- High corrosion resistance

- Can differ in strengths

- Offers high malleability but lower hardness

- Gold-like appearance makes it great for decor

Each metal offered at Charles Richter Metatcraft has its own unique metal properties. Contact us to learn more about the specific benefits of our different metals, including deep drawn brass.