Maintaining your metal stamped parts is just as important as the decision made to invest in purchasing them. At Charles Richter, we take pride in being a worldwide manufacturer that offers deep drawn metal stampings and custom metalwork services for nearly all applications across the industry. We have been using stamping presses for more than a century, manipulating metal into unique deep drawn parts. Our products are built-to-last and made with each customer in mind – from dimensions, to material, to order size. With trust at the foundation of our metal services, we apply our stamping knowledge and skills to creating both functional and beautiful pieces to fit our client’s needs.

We understand the importance of providing our clients the best experience that will allow them to enjoy perfect custom metal stamping and embossing. This level of attention to detail is all the more reason we know your metal stamping experience with us doesn’t stop there. Once your order of metal parts is in your possession, you’re probably thinking, “What next?”Now that you invested in the best metals, it’s important to learn the best way to properly maintain them too to extend their life and make sure they are performing at the highest level in any application.

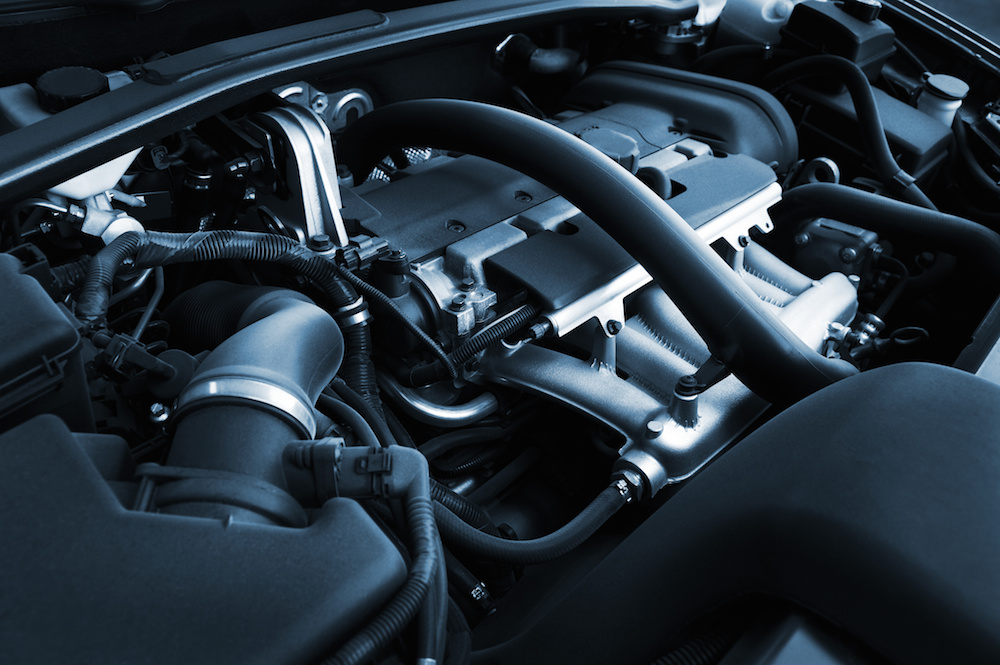

Stamped metal parts for lighting, medical, automotive, appliances and even aerospace and aircrafts are just a few services our metals are used for. With such a variety of purposes, it’s no wonder each part requires specific cleaning to best maintain it. Provided is a list of not only recommendations for upkeep of stamped metal parts but also a variety of other metal parts in the field and how to best maintain them.

Cathode Plates

The stainless steel cathode plates are often contaminated by dust, light soils, and remnants from grit blast. The process for cleaning this part requires washing followed by ambient blowoff to make sure the part is left 100% dry. You’ll know the part is cleaned to standard when debris does not exceed 20 microns.

Deep Drawn Tank Heads

Steel and stainless steel deep drawn tank heads are typically contaminated by grinding dust and oil. To make sure this product is clean it needs to be washed, rinsed, applied ambient blowoff, and pass an oil break free test. Given the wide size range of deep drawn tank heads this can often prove to be a time consuming task.

Forging Dies and Fixtures

Forging dies and fixtures that come in many assorted sizes are often contaminated by grease, oil, and manufacturing soils from the forging process. This cleaning process is one of the most straightforward methods as it only requires washing and inspecting that the parts are visually clean. Depending on the size and weight of the parts, this can prove to be difficult, but on a positive note it does not matter how or if the parts are dried after.

Hydraulic Cylinders

Typical culprits that affects iron hydraulic cylinders would be coolants, manufacturing soils, and loose mill scale from hot rolled steel. Such debris on the hydraulic cylinders need be only cleaned by washing, visually inspecting it’s clean, and letting it air dry. Although it’s an easy enough process, difficulty can arise depending on the narrowness/width and overall length of the cylinder. Such issues can be combatted by getting a part washer designed for the nozzle to fit into the crevices of cylinders.

Small Parts

Small or micro parts are often made from aluminum, steel or stainless steel and are typically negatively affected by cutting oils and coolants. Cleaning these parts requires washing, rinsing, and most importantly heated blowoff until 100% dry.

Stamped Metal Parts:

Finally, consider deep drawn stamped parts, the specialty here at Charles Richter. These products range in size and can be made for standard or custom applications. They often show signs of corrosion and debris from manufacturing oils and stamping lubricants. Often times these are crucial parts to one’s company (and manufacturing process) and requires strict cleaning standards of nearly as much debris removed as physically possible. Such maintenance requires washing, rinsing, rust inhibiting the product, followed by a heated blowoff until 100% dried. Make sure the parts are properly lubricated before and while in use to extend their longevity and prevent unnatural wear and tear.

In our time in the metal stamping industry, we’ve come to understand that different industries have different needs and require different products. As unique and customized as all the products are, each requires proper maintenance and care to make them long-lasting and function as they should. Regardless of the industry and the specifications, we will be able to meet your company’s needs by producing the highest quality products to your requests, but it’s up to you to apply proper treatments and care to secure the value of your products. By applying some of these maintenance tips, we’re confident to say that products from Charles Richter are built-to-last.